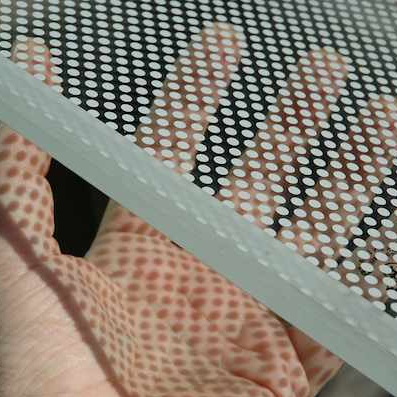

Ceramic frit glass is a new type of glass with characteristic of anti-acid, anti-alkaline, high security and strong decorative effect. All kinds of patterns and colors are printed onto the surface of glass with printing in paint by printing machine. The paint will be permanently sintered onto glass surface after drying and tempering.

Ceramic Frit Glass

Feature

- High intensity, safety, heat impact resistance with all kinds of performances which tempered glass has.

- Diversity of color and pattern are available according to customer’s requirement, outstanding decorative effect.

- Ceramic frit glass can absorb and reflect partial sunlight, has obvious sun shading function. It can be made into color glazed flat tempered glass and semi-tempered glass.

- Applicable to glass curtain wall, skylight, door and window, indoor partition and decoration, furniture and household appliance which request unique decorative effect and sun shading function.

Colour Coated Glass (Placoat)

Platicoat glass is an opaque glass with colour specially designed for residential and commercial interior applications. This typically used for indoor wall covering and widely used in furniture such as wardrobe door, cupboards, kitchens cabinet, retail outlets display case, restaurants front desk and offices partitions. Platicoat meets the demands set by current interior architectural design trends and is easily combined with other materials such as wood, steel or stone. A high quality paint on the back of the glass gives it an opaque appearance. The coating can be choose on your passionate colour according to any RAL, Pantone code and paint manufacturers brand or code for personalized colours. This product can be coated on any thickness and type of the glass: float glass, tempered glass, pattern glass and laminated glass.

Feature

- Easy maintenance and clean

- Contemporary look

Tempered Glass Heat Soak Treatment

Tempered glass is destructed without any external mechanical force, which called self-destruction. Currently self-destruction of tempered glass is unpredictable and inevitable. In order to reduce self- destruction as much as possible, PSG adopts international advanced technology-heat dip processing stove.

- Heat-soak processing Tempered glass is put into dipping stove and heated, and finally cooled down after heat preservation. After above processions, vulcanized nickel contained in tempered glass reaches the stable condition, and stress of interior glass tend to equilibrium, thus reduce self-destruction of tempered glass. Heat dipping can make particles or bubbles inside glass destroyed during processing. Thus self -destruction of tempered glass can be largely reduced after heat dipping treatment.

- Main factor for self-destruction of tempered glass During processing of tempered glass, vulcanized nickel crystal existed in interior glass will transfer to mini Size. High-temperature alpha crystal when excess of 380℃. During cooling down, this kind of alpha crystal is frozen down not transferring to low-temperature beta crystal. With time elapsing, alpha crystal gradually transforms as beta crystal. When alpha crystal transformed to be beta crystal, its expanding size produces additional tensile stress. The double increment of stress intensity causes self -destruction of tempered glass. This is the main factor of self -destruction of tempered glass.

- The other factors of self-destruction tempered glass: If the different shape glass and the drilled hole glass are easy to rupture, the installation process armored glass to support on both sides forms in the condition, the glass transporting and the installment, the maintenance process which the influence, the wind load computation is smaller than actually occurs on the other hand, deeply scratches, on the one hand to the glass surface explodes the mouth to explode and so on.

CNC Process & Edge Work

The latest technology CNC help turn ideas into successful and precise glass product. The CNC can help us to process mill, grind and polished any odd shape glass through the innovative and advance software. Edge and glass processing works enhance the aesthetic appeal of glass, thus encouraging specifies and users to choose the wide applications of glass.

We can provide the edge work as below:

- Drilling

- Notching

- Beveling

- Flat edge

- Round edge

- OG edge

- 2G & 3G edge

Mirrored Glass

Keng Ying Glass uses the latest technologies to manufacture and supply beautifully reflective mirrors. It has been proven to be durable and long lasting. Mirrors can be found in almost every interior. They expand and enhance spaces, reflect light and are no longer limited to bathroom furniture since they are available in a wide range of colours and finishes. We are carrying the world class brands such as Guardian UltraMirror® and GC Mirox MNGE. The glass combines incredibly clear reflections with high durability and corrosion resistance. It’s ideal for any interior spaces like retail, hospitality areas, houses and etc. Our ranges include standard high-quality mirrors, premium mirrors, antique mirrors & more.

With the increasing demand of customers from various industries, Keng Ying has been constantly increasing our company’s glass supplies of various kinds. These glass supplies are specially designed to be used in different industry according to its usage. Being a trusted glass manufacturer Malaysia which has operated our business for many years, Keng Ying is developed sophisticated and quality glass supplies to meet customers’ satisfactions.